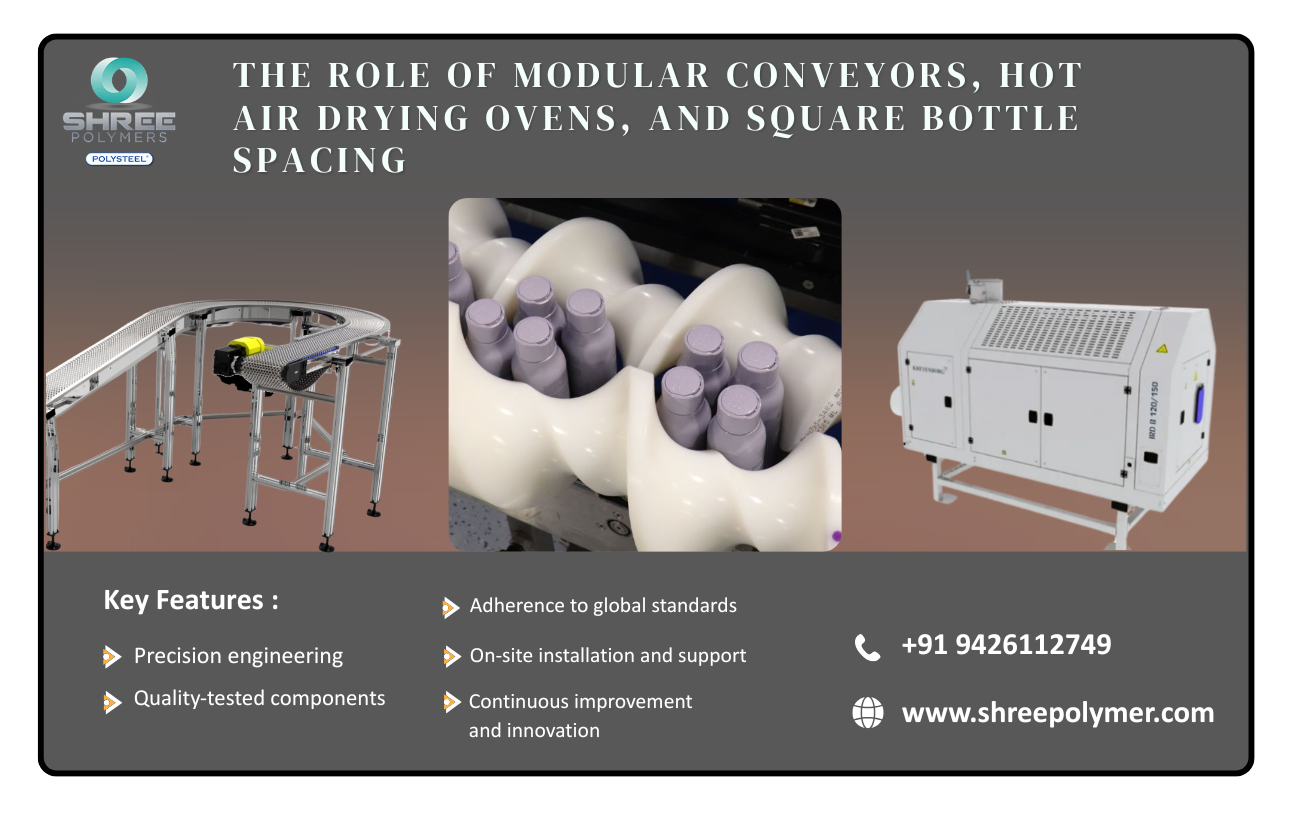

Optimizing Your Production Line: The Role of Modular Conveyors, Hot Air Drying Ovens, and Square Bottle Spacing

In the fast-paced world of manufacturing, efficiency is more than just a goal—it's a necessity. With profit margins and market demands tighter than ever, optimizing every aspect of your production line is crucial. Three critical components can significantly boost your production efficiency: modular conveyors, hot air drying ovens, and effective square bottle spacing. In this article, we explore how these elements integrate to enhance performance and product quality.

The Versatility of Modular Conveyors

Modular conveyor is a transformative addition to any production line, offering flexibility, durability, and speed. Unlike traditional conveyor systems, modular conveyors can be adjusted and customized to adapt to changing production needs. This flexibility is invaluable for facilities that handle a variety of products, as the configuration can be tailored to handle different weights and sizes seamlessly.

Moreover, setting up modular conveyors is generally less time-consuming, allowing production lines to minimize downtime during installations or upgrades. The ease of maintenance and ability to add or remove modules as needed can significantly reduce operational costs and enhance throughput.

The Efficiency of Hot Air Drying Ovens

Incorporating hot air drying oven into your production process, especially after tasks such as coating, painting, or washing, ensures that products are adequately dried and ready for the next phase quickly. These ovens are designed to deliver consistent drying through controlled heat distribution, which is crucial for maintaining product quality and speed. With precise temperature control, businesses can prevent common drying issues like uneven moisture distribution or overheating, both of which can affect product integrity.

Furthermore, the energy efficiency of modern hot air drying ovens helps in reducing utility costs, making them an economical choice for manufacturers aiming to improve sustainability and lower operational expenses.

Optimizing with Square Bottle Spacing

When dealing with the transportation and filling of bottles, especially square-shaped ones, precise spacing is essential. Proper square bottle spacing on conveyors can enhance the filling accuracy, reduce spillage, and prevent jamming, leading to smoother production runs.

Effective bottle spacing can be achieved through the use of guides and strategically placed pressure points within the conveyor system. These tools help maintain a regular pattern, ensuring each bottle is perfectly aligned for subsequent operations, such as labeling or packaging.

Synergizing the Components for Maximum Output

The individual benefits of modular conveyors, hot air drying ovens, and square bottle spacing are magnified when integrated into a cohesive system. By closely monitoring and adjusting these components, manufacturers can achieve production lines that not only move faster but also maintain high standards of quality and consistency. These adjustments can lead to significant improvements in throughput and yield, contributing directly to increased profitability.

In conclusion, investing in these advanced technologies and strategies paves the way for superior product management and enhanced operational competence. By optimizing your production line with these elements, you not only improve efficiency but also set the stage for scalable growth and innovation in your manufacturing processes.

Published on November 29, 2025 by Admin