Understanding Conveyor Belt Systems

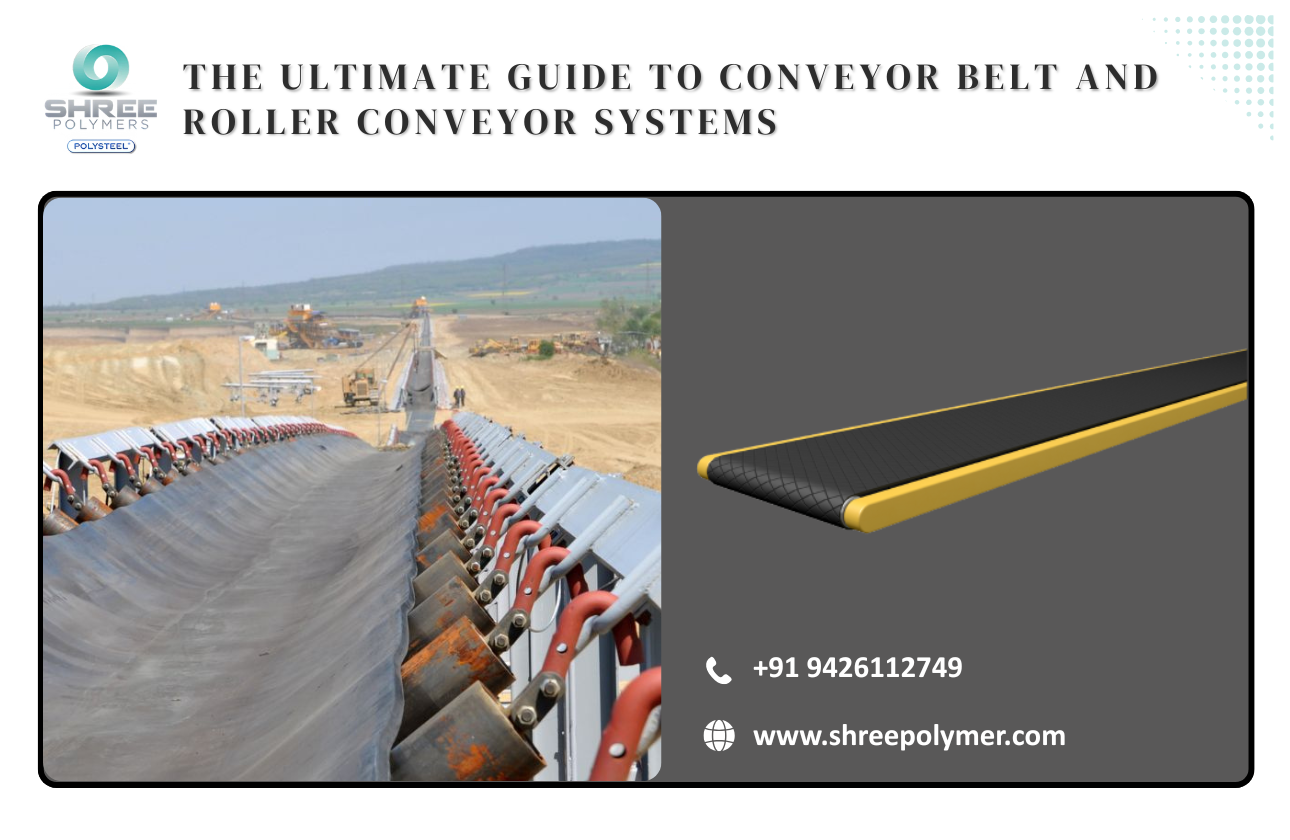

Conveyor belt system is an essential component in various industries including manufacturing, logistics, and distribution. They provide an efficient means of transporting materials between different points within a facility, significantly enhancing productivity and reducing labor costs.

A conveyor belt system consists of two or more pulleys, with a loop of conveyor belt that rotates around them. The belt acts as a surface to transport items from one end to the other. These systems can be customized to meet specific requirements, handling everything from small and delicate products to large and heavy items.

Types of Conveyor Belt Systems

There are several types of conveyor belt systems, each suited for particular applications:

- Flat Belt Conveyors: The most common, used for transporting general materials and goods.

- Modular Belt Conveyors: Made of interlocked pieces, ideal for transporting food due to easy sanitation.

- Incline/Decline Conveyors: Used for moving items across different elevations.

An Overview of Roller Conveyor Systems

Roller conveyor systems are another popular material handling solution, characterized by a series of rotating cylinders or rollers. These systems are particularly effective for moving items with a flat bottom surface and can be powered or unpowered.

They are widely used in warehouses and manufacturing plants due to their flexibility and efficiency in moving products through various stages of production and packaging.

Benefits of Roller Conveyor Systems

- Versatility: Suitable for a range of industries and applications.

- Scalability: Easy to expand or reconfigure to meet changing needs.

- Cost-Effective: Lower initial investment and maintenance costs compared to other systems.

Choosing a Reliable Roller Conveyor Supplier

When selecting a roller conveyor supplier, there are several factors to consider to ensure you receive a product that meets your requirements and offers long-term reliability.

Key Considerations

- Experience and Reputation: Look for suppliers with proven industry experience and positive customer feedback.

- Customization Capabilities: Ensure the supplier can provide customized solutions tailored to your specific operational requirements.

- Quality of Materials: Verify that the supplier uses high-quality materials to ensure durability and longevity.

- Customer Support: Evaluate the supplier's commitment to providing ongoing support and maintenance services.

In conclusion, whether you are looking to integrate a conveyor belt system or roller conveyor systems into your operations, understanding their features and benefits is crucial. Additionally, selecting the right roller conveyor supplier can make a significant difference in optimizing your material handling systems for better efficiency and productivity.

Published on November 26, 2025 by Admin