Optimizing Material Handling Systems with Bottle Grouping Screws, Feed Screw Spacers, and Bucket Conveyors

In the competitive world of manufacturing and packaging, efficiency and precision in material handling are paramount. Making strategic upgrades to your conveying systems can boost productivity and ensure smoother operations. This is where components like bottle grouping screw, feed screw spacers, and bucket conveyors come into play.

The Role of Bottle Grouping Screws

Bottle grouping screws are essential in sectors where precision and timing are crucial, such as bottling plants. These screws ensure that bottles are grouped uniformly before they are capped or labeled, reducing the likelihood of errors and increasing overall efficiency. By maintaining a steady rhythm, these screws facilitate seamless transitions through various stages of the bottling process.

Enhancing Precision with Feed Screw Spacers

Feed screw spacer is indispensable when you need to maintain precise spacing and alignment. In systems where components must be delivered at exact intervals, feed screw spacers ensure consistency. They work in conjunction with other elements of the conveyor system to keep production lines running smoothly without unnecessary stoppages or delays.

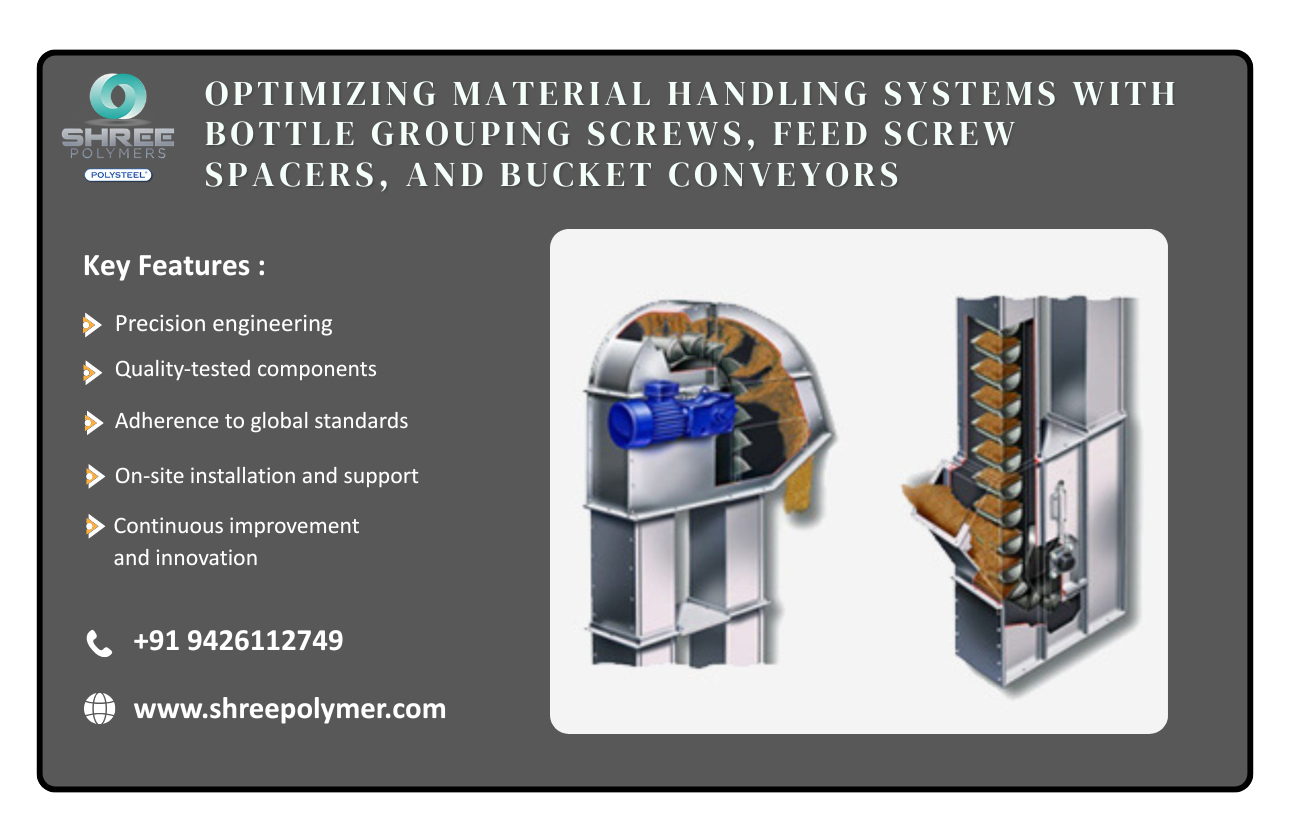

Boosting Efficiency Using Bucket Conveyors

Bucket conveyor is particularly effective in transporting bulk materials. Their design allows for the easy movement of solids, granules, or powders from one point to another, which is vital in industries like food processing, pharmaceuticals, and chemicals. The enclosed system of a bucket conveyor not only safeguards materials from contamination but also decreases spillage, thus enhancing operational cleanliness and resource management.

Integrating the Systems

When bottle grouping screws, feed screw spacers, and bucket conveyors are integrated into a unified system, they transform the workflow into a highly efficient production line. Manufacturers can tailor these solutions to specific needs, whether they are working with liquid, solid, or other forms of products.

Investment in these components often leads to significant returns through boosted productivity, reduced waste, and improved product consistency. By carefully planning and implementing these technologies, companies can remain competitive and responsive in their sectors.

Conclusion

Optimizing your material handling systems does not simply stop at adopting new technologies; it involves a strategic understanding of how different components can work together. Bottle grouping screws, feed screw spacers, and bucket conveyors represent pivotal upgrades that can drive efficiency and precision throughout your operations. For companies seeking to enhance their production capabilities, these solutions offer substantial benefits, ensuring operations are not just faster, but also more reliable and sustainable.

Explore the potential of integrating these conveying solutions in your industry today!

Published on December 2, 2025 by Admin