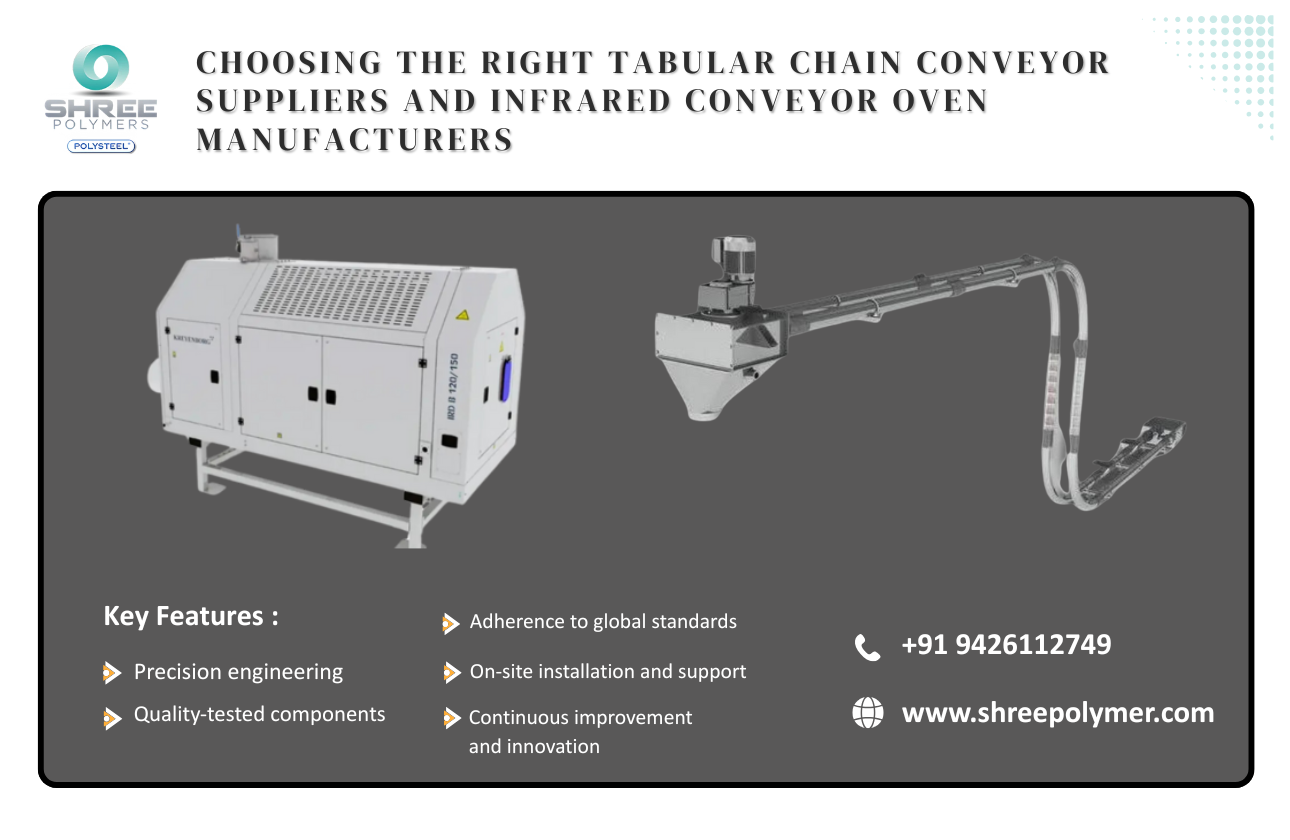

Optimizing Industrial Efficiency: Choosing the Right Tabular Chain Conveyor Suppliers and Infrared Conveyor Oven Manufacturers

In the realm of industrial manufacturing, efficiency and precision are paramount. Whether it's automating assembly lines or maintaining consistent product quality, the equipment chosen plays a crucial role. This is where selecting the right tabular chain conveyor suppliers and infrared conveyor oven manufacturers becomes vital. Moreover, components like the bottle spacer screw, although small, have a significant role in maintaining seamless operations.

Understanding Tabular Chain Conveyor Suppliers

Tabular chain conveyors are essential in industries where there is a need to transport materials over long distances effectively. These conveyors are renowned for their durability and ability to handle diverse products, from raw materials to finished goods. When selecting your tabular chain conveyor suppliers, consider factors such as:

- Material Quality: Ensure that suppliers use high-grade materials that can withstand your industry’s wear and tear.

- Customization Options: Look for suppliers who offer customization to meet specific operational needs.

- After-sales Support: Adequate support for maintenance and repairs can ensure minimal downtime.

The Role of Infrared Conveyor Oven Manufacturers

Infrared conveyor ovens are indispensable in processes that require precise heating, such as baking, drying, or curing. Choosing reliable infrared conveyor oven manufacturers should involve:

- Energy Efficiency: Opt for ovens that offer superior energy efficiency, thus reducing operational costs.

- Consistent Temperature Control: Ensure the manufacturer provides ovens with advanced temperature controls for consistent product quality.

- Space Optimization: Consider the oven’s footprint relative to your plant space to ensure it fits well within your operational layout.

The Subtle Importance of a Bottle Spacer Screw

While conveyors and ovens handle large-scale operations, the bottle spacer screw plays a critical role in precision tasks. Used predominantly in bottling plants, these screws ensure bottles are correctly spaced for filling or labeling operations, thereby preventing spillage and mislabeling. The ideal bottle spacer screw should feature:

- Durable Material: Made from materials that resist wear and can handle fast-paced operations.

- High Precision: Designed with precision to avoid product loss and ensure production efficiency.

- Compatibility: Must be compatible with existing machinery to ensure easy integration.

Conclusion

Investing time in selecting the right tabular chain conveyor suppliers, infrared conveyor oven manufacturers, and quality components like the bottle spacer screw can have a profound impact on productivity and cost-efficiency. As industries move towards more automated and precise operations, these choices will define the quality, reliability, and cost of your operations.

By keeping these considerations in mind, manufacturers can ensure their production line is both efficient and sustainable, ultimately leading to enhanced production outputs and improved product quality.

Published on November 28, 2025 by Admin